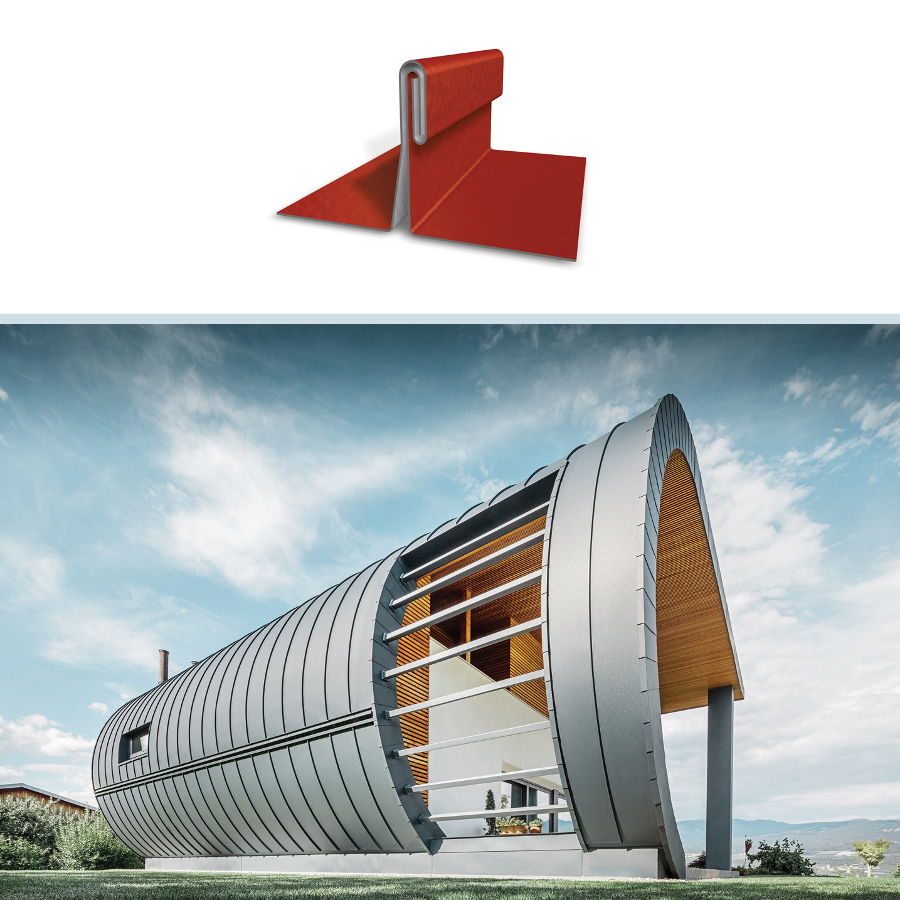

Versatile and supple: Prefalz is easy to work with and thus offers great creative scope for your roofing.

Prefalz offers numerous options in terms of colour and shape. Thanks to the aluminium material, it is more supple than most comparable folding materials and is thus particularly easy to work with. With its low weight of between 2.2 and 2.3 kg/m², depending on the tray width, Prefalz is suitable for roof renovations as well as for new buildings, as it adapts perfectly to the different building methods. It can also be expanded with the wide range of PREFA system accessories.

From barrel roofs to complex roof extensions, domes or large-scale roofs — Prefalz offers countless individual design options. Folds and bends won’t affect the paint quality at all: Prefalz is supplied in numerous colours with a smooth or stucco surface, as required.

Prefalz coils can be ideally used as complementary coils for PREFA small-format products – suitable for various connections and flashings in the dimensions 0.70 × 1,000 mm (coil dimension 60 kg).

It should be particularly emphasised that the Prefalz aluminium roof complies with reaction to fire classification “A1” – thus non-combustible - according to EN 13501-1.

Prefalz benefits

For a wide range of applications from curved arched roofs to complicated roof extensions, domed roofs, classic gable roofs or large-scale roofs.

Easy to work with, highly resilient easy to work with even at low outside temperatures.

40-year guarantee on material and colour for products with P.10 surface.

Fire protection - Prefalz non-combustible (A1).

Complete system - Extensive and coordinated system accessories, ensure safety and durability.

Numerous design options - Very wide selection of standard colours as well as smooth and stucco surface, suitable for PREFA’s complete system.

Environmentally friendly - Aluminium is 100% recyclable without a loss of quality.

Long service life - Aluminium does not rust.

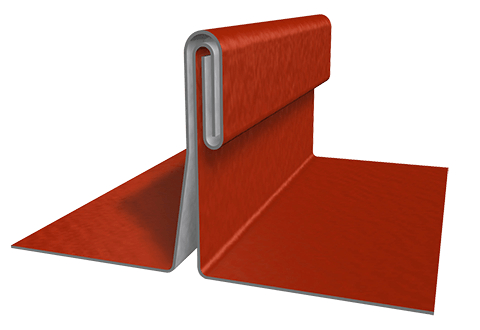

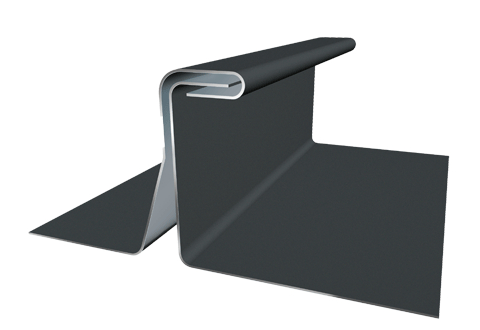

Fold details

In the case of standing seam coverings, pre-profiled or folded panels are folded together to create a rainproof joint. The angled standing seam is primarily used for façades, while the double standing seam is used on roof surfaces. The following two images show the cross-sections of double and angled standing seams:

Installation systems and application types

Prefalz strips, also known as panels, are produced on roll formers made of strip sheets.

These panels can be installed using sliding clips up to a length of 12 m. If appropriate additional measures are taken, longer panels are also possible. The long sheets allow easy, safe and economical installation of the roof covering. The panel may always have the same width or may have different widths in special cases.

Mirror roofings and panel coverings consist of panels which are interrupted by transverse seams. They are often used in buildings with particularly high wind loads or are also used for design reasons.

For low pitched roofs with a roof pitch from 3°

Expert tip

Roofs designed with Prefalz have the highest stability and durability. PREFALZ is suitable for very low pitched roofs* with a roof pitch from 3° and can also be installed well even at low temperatures.

*Observe country-specific standards and specialist guidelines.

Overview of Prefalz colours

Prefalz offers a wide range of standard colours, mainly in P.10 quality, with a 40-year colour guarantee. The paint coating is applied and fired in several processing stages in the coil-coating process. As a result, the coating layer is malleable and very weather-resistant.

Notes

- The RAL values stated are merely approximate values (~), some of which may differ vastly from the original PREFA colour and, under certain circumstances, may not reflect the subjective perception of the colour.

- Above all for colour quality P.10, it is almost impossible to define values due to the surface structure.

- Plain aluminium: The guarantee does not cover surface appearance alterations caused by processing and environmental influences. Follow the instructions.

- Metallic colours may vary in shade.

- To identify exact colours for complementary components please consult original samples.

Prefalz technical information

| Material |

coil-coated aluminium, 0.7 mm thick |

| Standard dimensions |

Prefalz for roofs: 0.7×500 mm; 0.7×650 mm

complementary coil: 0.7×1,000 mm |

| Weight |

approx. 1.89 kg/m²

actual consumption with Prefalz 500: approx. 2.3 kg/m²

actual consumption with Prefalz 650: approx. 2.2 kg/m² |

| Minimum roof pitch* |

3° (approx. 5%)

* Observe country-specific standards and specialist guidelines. |

| Supporting substrate and separation layer* |

on fully boarded substrate (at least 24 mm); separation layer as required

*Observe country-specific standards and specialist guidelines.

|

| Fastening |

PREFA preformed fixed and long sliding clips (stainless steel) according to static requirements |

Caution: Mixing Prefalz FALZONAL coils with colour-coated aluminium from competitive manufacturers, but also with FALZONAL® material of supposedly the same colour, should be avoided at all costs because of the different paint qualities and subsequent differences in weathering. Only in this way can you enjoy a harmonious-looking façade even after many years. This must also be observed for weatherings, cappings and the like.

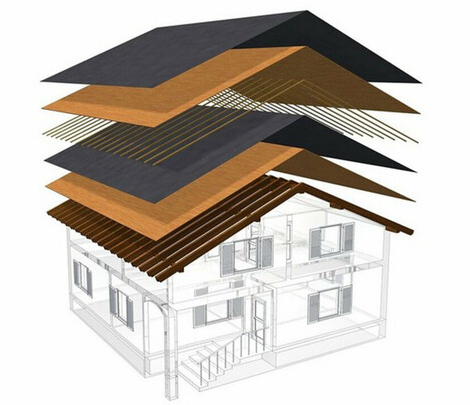

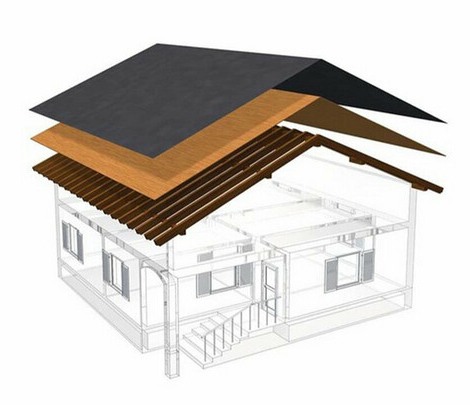

Roof structure

PREFA aluminium roofs are produced with a ventilated substructure, with the roof cover and thermal insulation layer separated by a ventilated gap. This means any occasional condensation can be wicked away.

It is mostly the roof membrane that is ventilated, as shown in the first picture. However, the whole attic space can also be ventilated (second picture).

Separating layers

Separating layers arranged directly under the roof covering can fulfil a variety of tasks. Whether a separating layer is used or which separating layer is to be used should thus be already taken into account in the planning phase.

Separating layers can:

- protect the wooden formwork or wood-based panels from moisture during the construction phase.

- improve sound insulation (acoustic decoupling).

- compensate for minor unevenness in the roof structure.

- improve the extension and contraction of the trays.

- protect the metal on the underside against damaging alkaline influences and possible harmful chemicals in substrate.

- support the roof covering and the sub-roof with regard to the rainproof function.

Depending on the function that a separating layer is to assume, a suitable product must be agreed with the manufacturer of the separating layers. If, for example, the separating layer’s function is to provide additional sound insulation, the use of stronger, heavier bitumen separating layers (e.g. BauderTOP UDS 3 NK or similar) is recommended. If the separating layer is “only” intended to protect the substructure during the building phase, a thinner bitumen separating layer can be used (e.g. BauderTOP TS 40 NSK or similar).

BIM

BIM

CAD

CAD

BIM

BIM

CAD

CAD

BIM

BIM

CAD

CAD

BIM

BIM