Working in tandem, two MEVA Automated Climbing (MAC) systems built one storey every five days on these four residential towers in Manchester

The Goal

To build four apartment buildings up to 202 m high in just four years

Four buildings were planned to be built in two phases near Manchester city centre, with two buildings per phase. The four residential towers are at the heart of a holistic development concept which brings together homes, recreational facilities, and commercial areas.

The Project

Summary:

In total, 194 storeys needed to be cast across the four buildings in a short timeframe and within an urban setting.

Challenge:

A high degree of precision is required for the MAC system, which was an even greater effort for two systems to be in use for a period of four years.

The Solution:

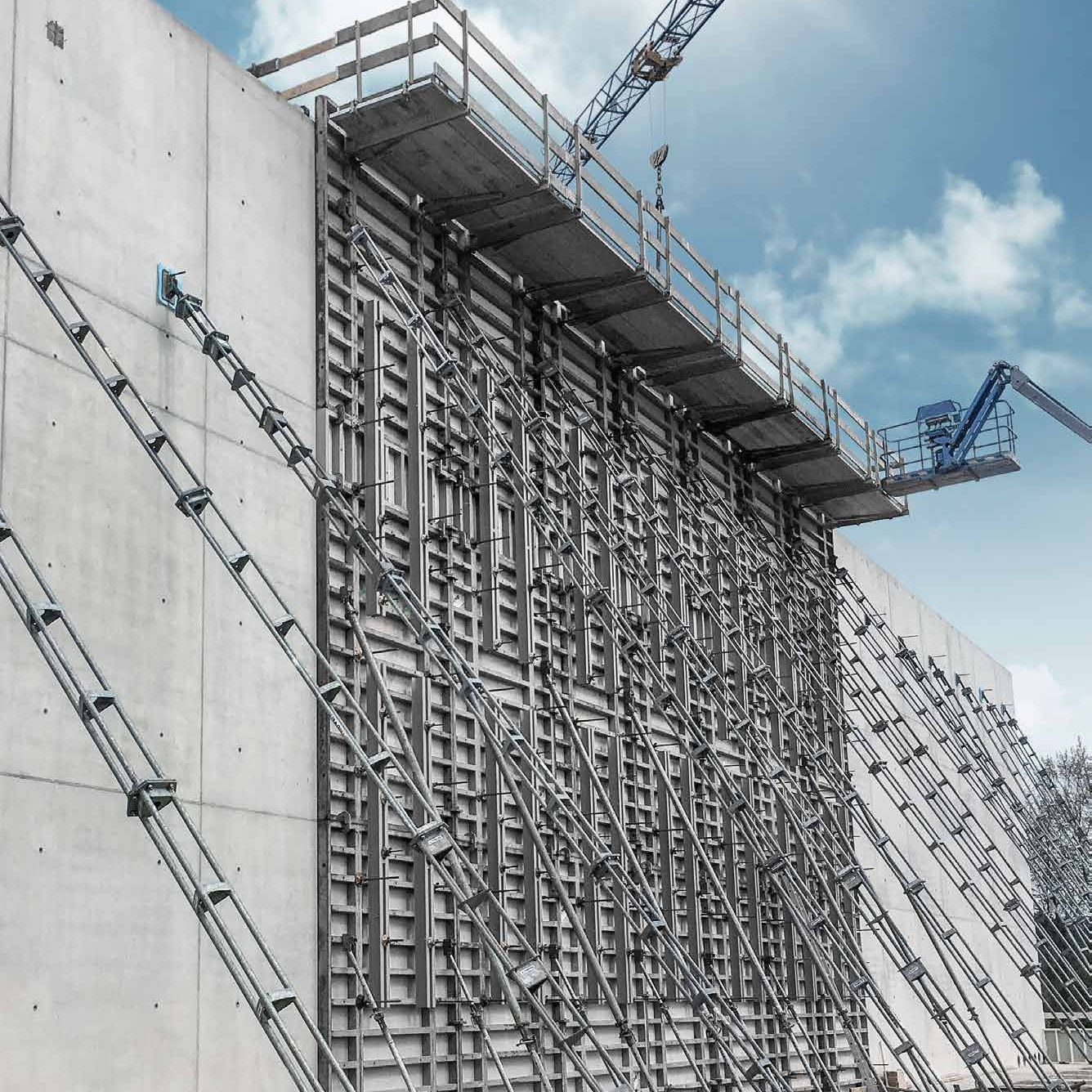

Close collaboration with the client

By closely liaising with the client, MEVA UK were able to help advise and plan on the best setup for the project. A project of this size is the perfect fit for the MAC climbing system, together with the Mammut 350 wall formwork. The system can be adapted from cycle to cycle to compensate for floor plans that differ in detail, or special shapes such as varying door openings.

However, precise coordination with all project stakeholders is exceedingly important with the MAC system. To guarantee that everything was perfect once installed on site, a highly specialised team of MAC experts from the UK and Singapore offices were involved in the planning. Together with the client, the early exchange of information and close collaboration meant that the design and construction progressed smoothly.

Rigorous design and planning

As soon as the finished construction plans were available, the technicians and structural engineers began the concrete design and calculation of the automatic climbing system. Basic components, such as control hydraulics, platforms, steel girders or working platforms are part of the standard equipment of every MAC system. Nevertheless, it is necessary to plan, inspect and adapt the systems afresh for every single construction project to suit the architecture of the building.

The design documentation, which contains more than 100 plans, was closely coordinated between MEVA and the construction company before production and materials procurement began. Furthermore, safety requirements had to be met, which are particularly strict in the UK. However, the MAC system meets these as a matter of course due to MEVA’s high standards.

Flexible Deployment

Four MAC systems for four high-rise buildings would be a logical assumption in order to rapidly complete the residential towers of between 37 and 66 storeys. However, costs also play a major role in a prestige building project such as this. Hence, the client opted to erect the four buildings into the sky above Manchester using two systems.

To achieve this, after completion of the first building the complete units must be relocated. However, this is reasonably straightforward, with the formwork panels being cleaned and checked for damage. The MAC system is then immediately moved into position on the new building core.

Rapid Construction

Once installed, the MAC system climbs at a remarkable pace – on average, the system was able to complete each 2.85 m high storey within four to five days on this project, which significantly accelerated the construction schedule. The uppermost of the four working platforms is then moved upwards by nine hydraulic cylinders, each with a capacity of 200 kN. The process takes about 60 minutes per storey (up to 4 m).

The Outcome

The four towers were completed in the desired timeframe, opening in 2020, thanks to the rapid core construction and swift relocation of the MAC systems.

Featured Products

- Climbing formwork, MEVA Automated Climbing (MAC) system

- Wall formwork Mammut 350.

Client: Renaker Build Limited

Project: Deansgate Square

Location: Manchester, UK

Architects: SimpsonHaugh and Partners

Engineering & Support: MEVA Formwork Systems Ltd, Great Britain, MEVA Formwork Systems Pte Ltd, Singapore.