MEVA modelled and planned a combined formwork system made up of custom and standard panels in order to build an architecturally challenging cycling tunnel in the German city of Mannheim

By bicycle to the BUGA trade fair: Underpasses can be so beautiful.

MEVA modelled and planned a combined formwork system made up of custom and standard panels in order to build an architecturally challenging cycling tunnel in the German city of Mannheim.

When the BUGA 23, last year’s national garden show in Mannheim, closed its doors on the 8th of October, around 2 million guests have had visited the huge flower and summer show in the city with a population of 300,000. Mannheim will retain a large part of the comprehensive restructuring work afterwards in order to produce a new “green lung” in the city. For example, the bicycle highway from Darmstadt located 50 km away and a uniquely designed tunnel that runs below a busy road and enables about 2,900 persons a day to reach the BUGA grounds comfortably and safely.

A refined structure with a length of 40 metres arches over the 4-metre wide cycle path and a separate 2.5-metre wide pedestrian lane: The “Am Aubuckel” cycling tunnel blends harmoniously into the surrounding landscape and proves that underpasses can also be attractive.

Complex preparatory work

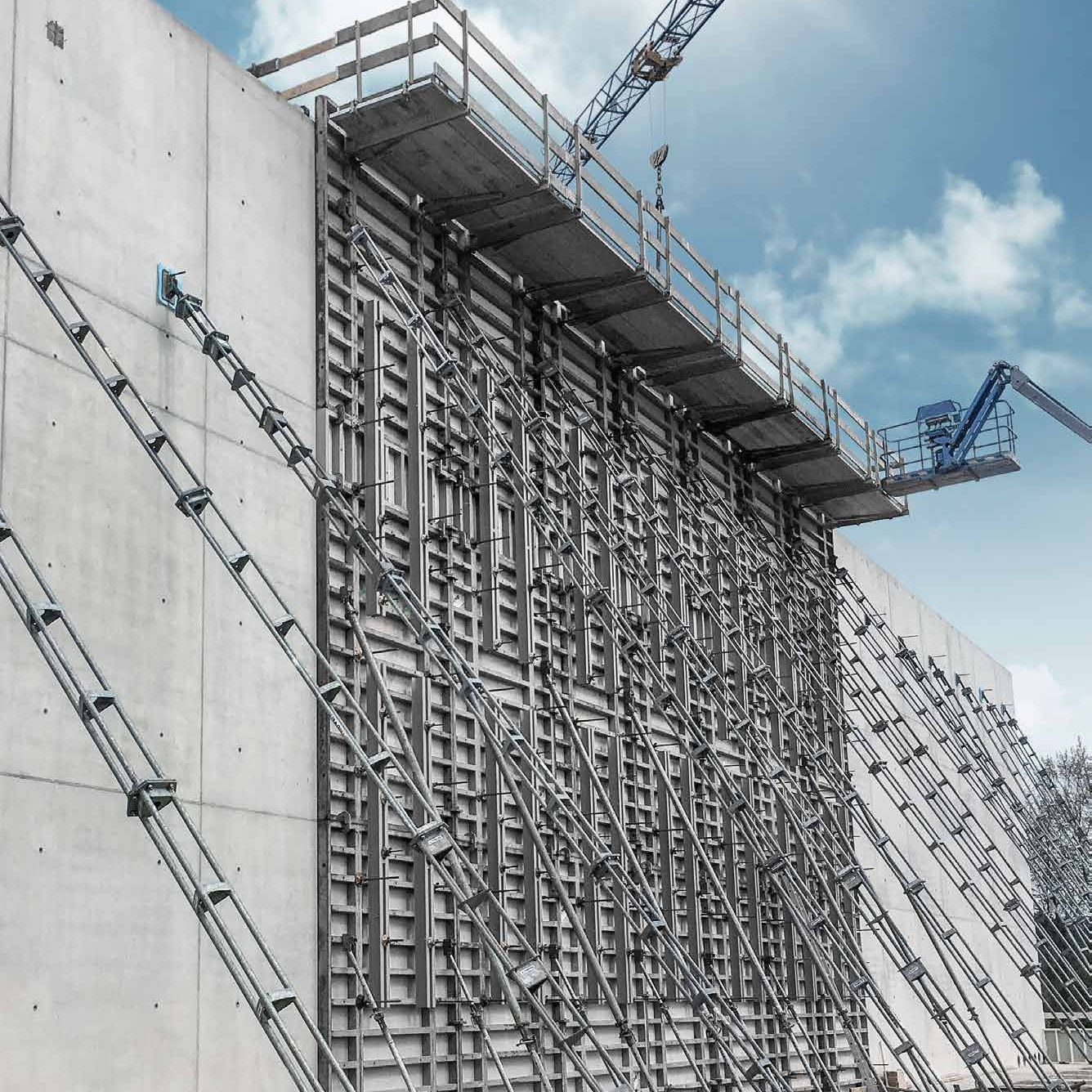

With its concave tunnel arch and one trumpet-shaped and one frog`s mouth-shaped entrance, the underpass is an eye-catcher. MEVA’s department for special formwork supported the execution of the difficult project with complex preparatory work and, besides the formwork, also planned a shoring tower construction capable of transferring large loads.

In order to keep the costs within reasonable limits, MEVA combined the complex special formwork panels, to the greatest extent possible, with the tried-and-tested frame formwork Mammut 350. The special formwork panels were used, in particular, in the visible area, i.e. Inside the tunnel. As counter formwork in the lateral and upper areas, which were covered over with earth later on, Mammut 350 was able to play to its strengths. In addition, MEVA’s SK 150 brace brackets were used to transfer loads to the stop ends.

Almost every panel was unique

The special formwork, in particular, required extensive preparation work. The 3D drawing produced by the architects was refined, modelled and split up into a checkerboard pattern. Lastly, about 30 trucks loads of special panels were delivered to the second-largest city in Baden-Württemberg, easy to transport with a maximum width of 2.5 metres and primarily with lengths between 3.50 and 5 metres. Due to the different curvatures in the tunnel, almost every panel was one of a kind.

New alkus SF Flex panels in use

The special formwork panels consisted of wooden bodies covered with alkus SF Flex facings. These new plastic facings are particularly well suited for very tight bending radii and thus for challenging special formwork. Another advantage of the alkus facings is their insensitivity to humidity: They do not absorb water and do not swell or shrink. As it took several weeks to erect the formwork, install the rebars and pour the concrete for the entire tunnel, the formwork was exposed to the elements for a long period of time. However, this had no effect on the high quality of the concrete finish. This wouldn’t have been possible with a surface on the basis of wood.

The formworking process, and thus also the preparatory logistical work, was painstakingly planned by MEVA. The forming work started in the middle, at the apex of the tunnel, and then proceeded outwards on both sides. The concrete itself was poured in one cycle. MEVA was also able to contribute its know-how here and provide advice with regard to the optimum vibration technology. The tunnel was opened to cyclists and pedestrians on schedule for the start of the BUGA.

Below: The top of the new cycling tunnel was poured without final formwork and also in a single cycle. The result speaks for itself.

MEVA systems:

- Special formwork solutions

- Mammut 350 wall formwork

- SK150 brace brackets.

Project: "Am Aubuckel" cycling tunnel, Mannheim, Germany

Engineering and support: MEVA Schalungs-Systeme GmbH, Haiterbach and Munich office.