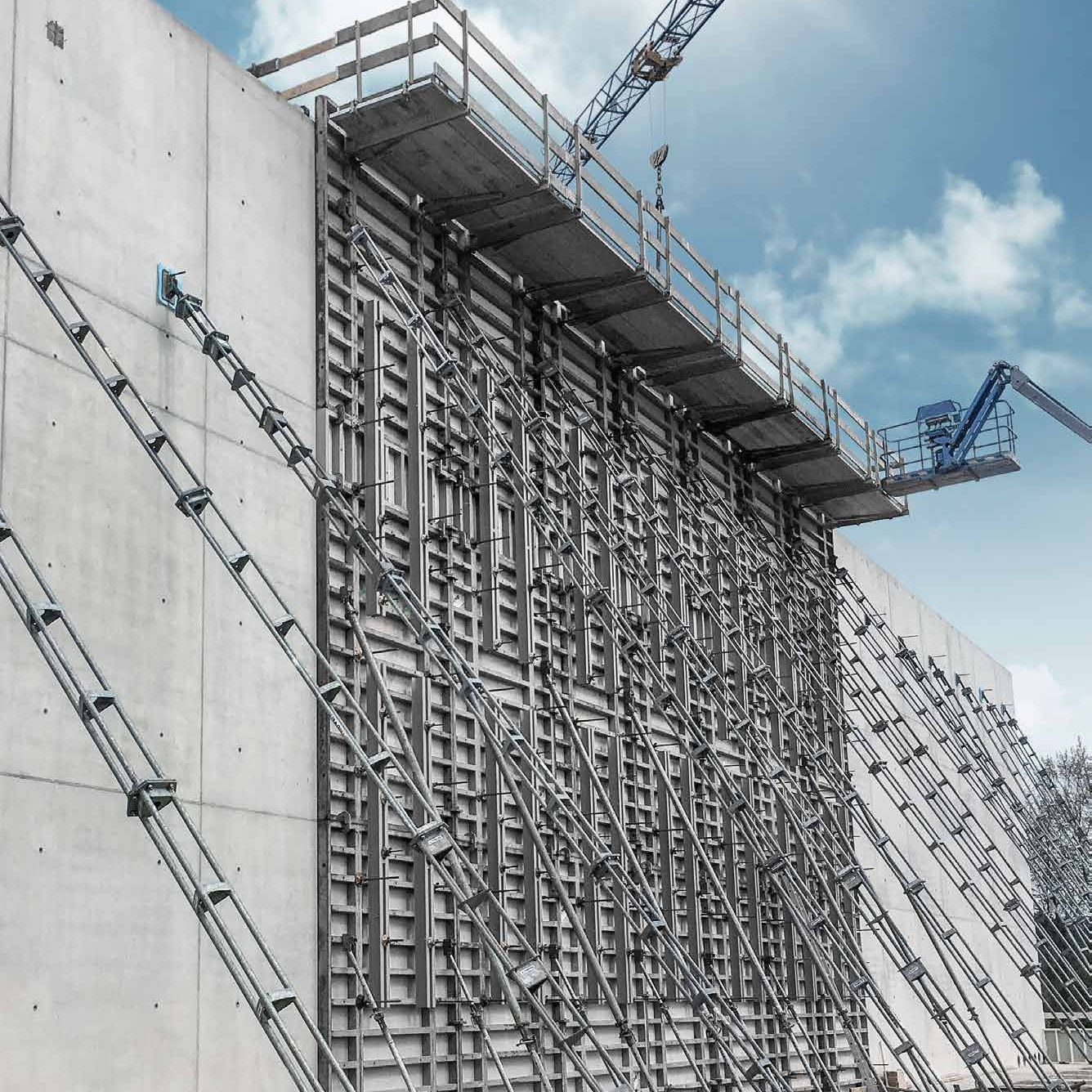

MEVA has developed and used both standard and special formwork, or a combination of both, to meet the forming requirements for these complex building parts

Bauunternehmung Granit Gesellschaft m.b.H.

The complex geometry, and five separate cores, of the central Library and Learning Centre presented a challenge even to the most experienced formwork engineers – but the result was a masterpiece in modern architecture.

The Goal

Increased capacity for Central Europe’s largest university of economics

The Vienna University of Economics and Business – originally designed to house 10,000 – had grown to become Central Europe’s largest university of economics and home to over 23,000 students.

The goal of this project was to use state-of-the-art architectural design and concrete construction techniques to increase capacity and to modernise this historic landmark.

The Project

Summary:

Dating back to 1898, the original building was founded as the Imperial Export Academy to prepare students for employment in international trade, before becoming a university in 1975.

Substantial expansion meant a requirement to extend the campus in Austria’s capital, with a further six buildings planned – four of which were erected using MEVA formwork and formwork solutions.

Challenge:

By far the biggest challenge was The Library and Learning Centre (LLC), with its five cores, inclined walls, each with a different complex geometry, and rounded corners with different radii.

The Solution

1. Special formwork meets more traditional methods

MEVA has developed and uses both standard and special formwork, or a combination of both, to meet the forming requirements for these complex building parts.

Steel formwork, for example, is used for rounded corners if required for structural reasons. Trapezoidal areas of inclined cylindrical corner areas are poured with special Mammut 350 wall formwork panels and special designs of MEVA’s circular column formwork Circo are used for the tilted and rounded corners.

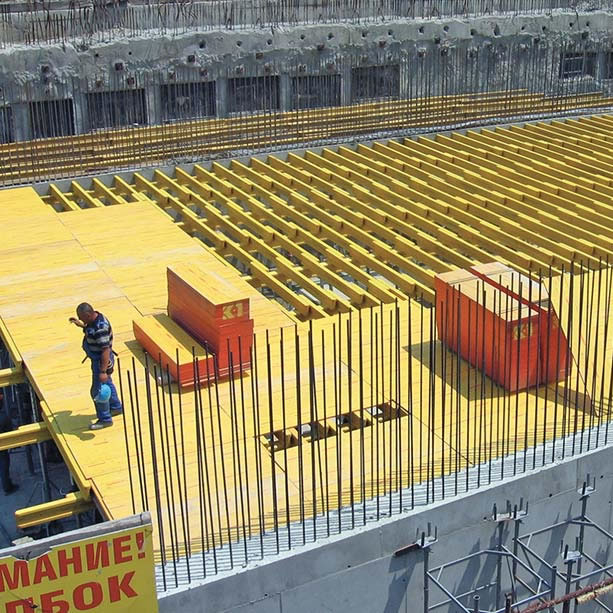

2. Detailed planning to achieve fanned out board patterns

The inclined core walls are poured with an architectural concrete surface and a board pattern is applied to them. The pattern is achieved with wooden boards attached to the Mammut 350 panels.

Since the front walls are inclined at different angles, the side walls have four different angles and are wider at the top than at the bottom. This requires detailed planning and a little “trick“ in order to achieve a consistent board pattern on the side walls, Jochen Moosmann.

On the left and right of the side wall, the boards, and thus pattern, are parallel to the adjoining front wall. Since the front walls are not parallel, the board pattern on the left of the side wall is inclined at a different angle to the pattern on the right. To compensate for the different angles, the pattern is fanned out in the middle section of the side wall.

The boards used for the fanning out section are wider at the top than at the bottom and their width ranges from 8 to 12 cm, depending on the fanning out area they are used for. The boards of a specific fanning out area always have the same size to achieve a homogeneous and consistent fanning out pattern.

The boards used for rounded walls are generally 8cm wide. MEVA engineers planned these patterns to be consistent on the entire multi-storey wall from the ground to the top.

3. All plastic-facing panels provide a smooth architectural concrete surface

The core walls have so-called inlays. They are areas with a smooth architectural concrete surface that optically interrupt the board pattern and are achieved with the alkus all-plastic facing that is standard in all MEVA formwork systems.

4. Inclined and curved canyon walls formed with special timber formwork

Another specialty are the canyon walls between the cores. Mostly consisting of beams and parapets, the canyon walls are also inclined and curved with different radii. They are formed with the Mammut 350 panels and then plastered. Rounded parts of the canyon walls are formed with special timber formwork.

5. Comprehensive on site support and careful detailing

The LLC was built by the Austrian contractor Granit from Graz, Austria. Work and staff are supported on site by MEVA Austria while all formwork solutions for MEVA and non MEVA standard and special formwork are planned by Application Engineering at the German MEVA headquarters.

The Outcome

Despite its complex geometry, the project – which brought together esteemed architects, engineers and construction experts from across Europe and Japan – was a huge success.

The LLC, designed by Zaha Hadid Architect now sits proudly at the heart of the city and is considered to be a masterpiece of modern architecture.

Featured Products:

- Mammut 350

- Circo

- MEP

- MevaFlex

- Triplex

- Special Formwork.