Combined office and commercial building "Gloria Berlin" built in a confined space

Precise coordination required

On the Kurfürstendamm, Berlin’s famous boulevard, time never stands still. The boulevard has already seen many changes and is constantly reinventing itself. During the construction of the combined office and commercial building "Gloria Berlin" directly next to the Kaiser Wilhelm Memorial Church, use was made of MEVA’s formwork engineering and planning expertise.

The name Gloria-Palast once referred to the most eminent movie theatres in the capital and lured cineastes and celebrities to the film festival on the "Ku’damm". In the new "Gloria Berlin" attractive retail businesses and offices will attract the customers in future. Within one year, by May 2020, the building shell was erected for two new combined office and commercial buildings with a total gross floor area of almost 25,000 m², large slab support spacing and large storey heights. The front of the building embraces architectural elements that reflect the Ku’damm’s history, and through the use of glass and natural stone, blends in harmoniously with the existing façades.

Two basement levels (the equipment level and the retail level), the ground floor and five upper floors as well as a set-back equipment floor with a steel structure were created on the exclusive building plot with a surface area of approx. 3,400 m². 14,500 m³ of concrete and 2,400 tons of steel were used, and 8,500 m² of reinforced concrete walls and more than 20,000 m² of reinforced concrete slabs were produced. The latter had to be produced entirely using a monolithic construction method, as the slabs up to and including that of the first floor were formed as Cobiax voided slabs and slabs above that level were formed with integrated concrete core activation.

Precise coordination required

The exposed location in the bustling city centre, difficult transport accessibility, hotels in the immediate vicinity and complicated site preparation: Flexibility and precise coordination were required on the part of the project team at Mark-A. Krüger Bauunternehmung led by the construction manager Mathias Lippski and foreman Enrico Seeger. And additional challenges also had to be mastered: To a large extent, the second basement level had to be built underneath technically indispensable construction pit bracing made up of steel pipes with a diameter of 60 cm. It was necessary to relocate district heating transmission lines and put them back into operation while the work was in progress. Also the concurrent renovation of the historical building on the adjacent plot Ku’damm 15 – which also belongs to the "Gloria Berlin" ensemble of buildings – required close cooperation and coordination with the neighbouring construction site. Last but not least, due to prevailing groundwater conditions, complex water drainage had to be practised up to the completion of the second floor in order to reliably build the basement levels up to a depth of approx. 8 metres in the pressurized groundwater.

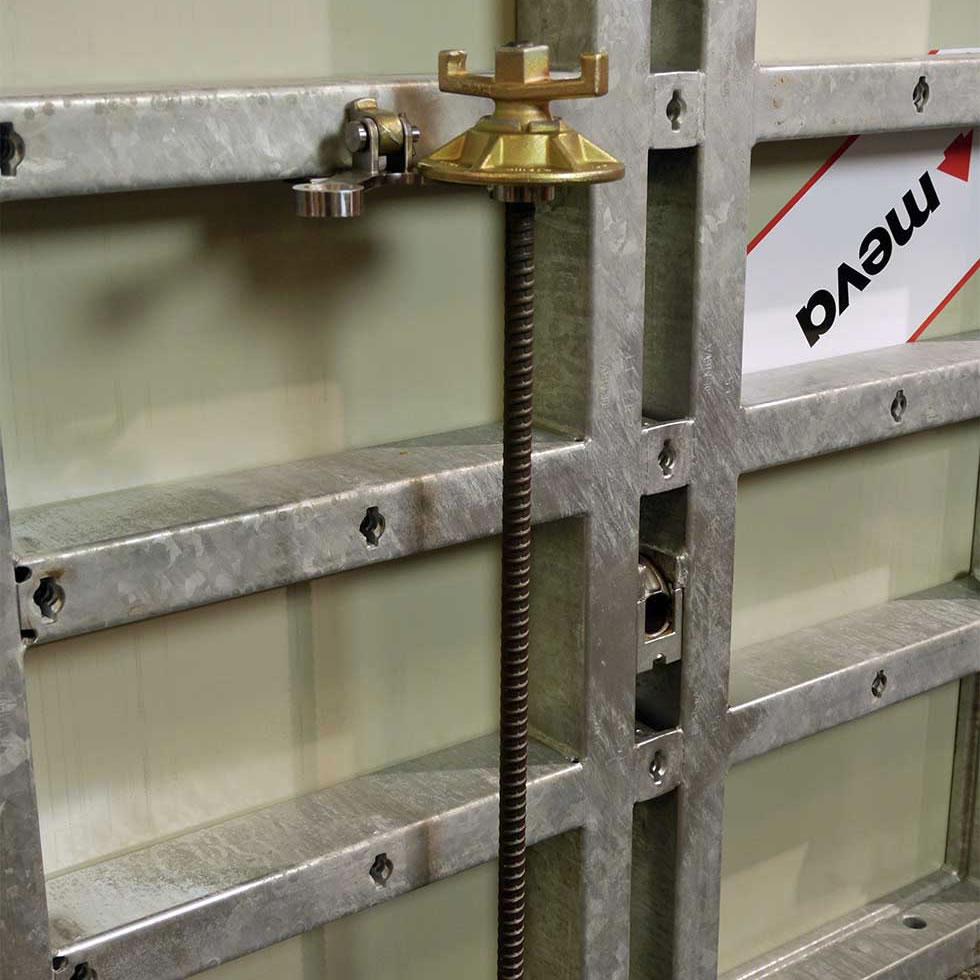

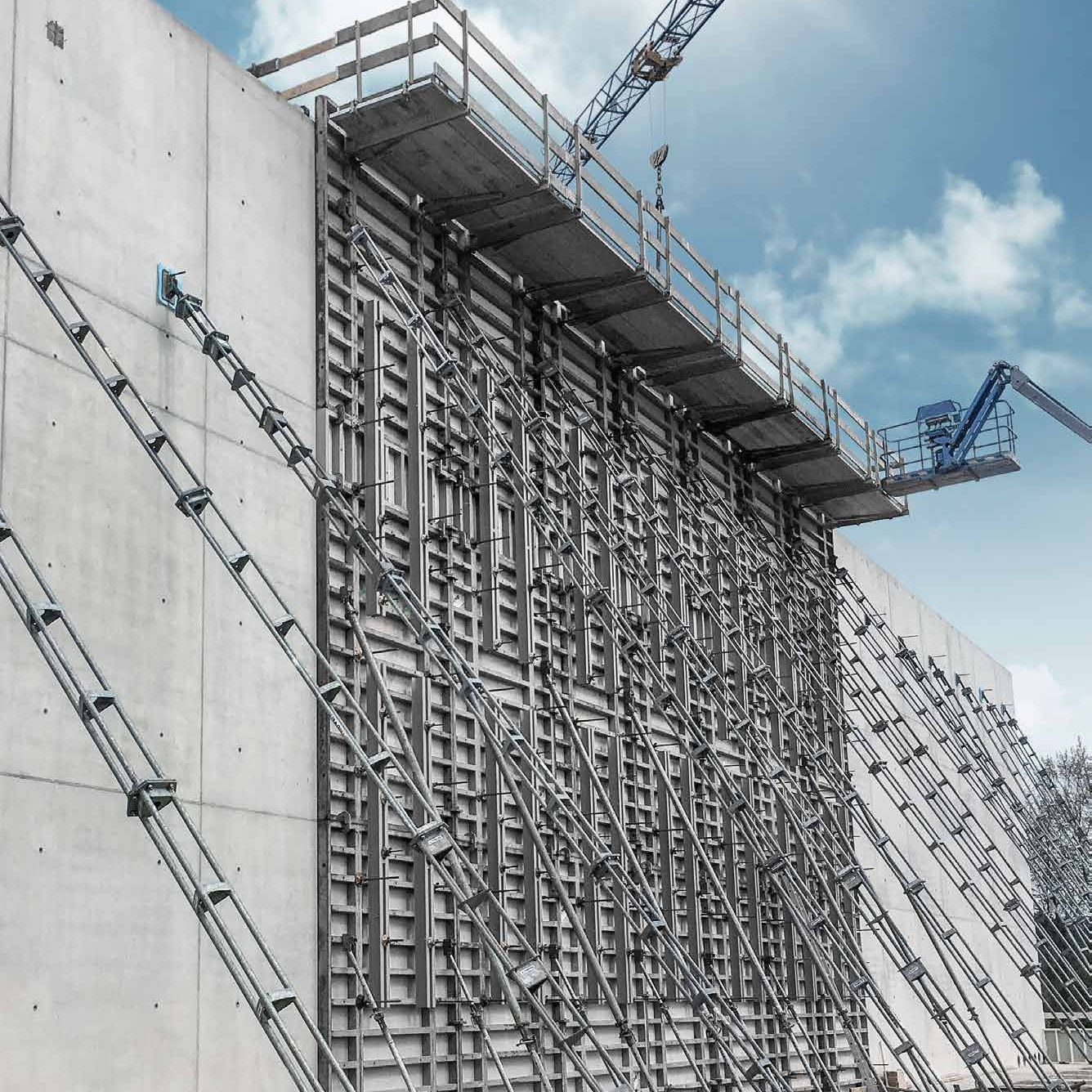

Because the groundwater conditions made it necessary to use a construction method with all-round "trough walls", the formwork for the outer walls of the two basement levels had to be tied from one side against the construction pit sheeting. Thanks to their compact design with a depth of only 2.45 metres, the robust STB 450 support frames simplified transport, space-saving storage and use on the construction site. They transferred the high loads from the formwork into the foundations without problem. However, there was a particular need for coordination with MEVA’s technical department in this context with regards to the high individual loads transferred by the support frames into the voided biaxial slab. Additional measures to safeguard against these loads were planned by MEVA and successfully implemented by the construction company. The economic Mammut 350 wall formwork system with a fresh-concrete pressure capacity up to 100 kN/m² had no problems with the large wall heights up to 5.20 m. Up to the second floor clearance heights of approx. 4.50 metres were required.

Maximum slab support spacing

3,185 m² of MevaDec panels were employed to pour the slabs of the combined office and commercial building. In order to achieve an airy, open atmosphere on each storey, Cobiax voided slabs were combined with steel-concrete composite columns up to the first floor. Due to the interplay between the weight-reduced slabs and the high-strength steel-concrete composite columns – and although the columns were slender throughout – it was possible to achieve a slab support spacing of approximately 9 metres. High-strength steel-concrete composite columns and beams were integrated. The slabs of floors 3 to 5 were formed with integrated concrete core activation in order to be able to use the solid structural elements to control the temperature of the building when the building is in use later on. Here, the construction company benefited from the use of MevaDec. The slab formwork made it easy to find flexible solutions in areas where pipes had to be routed through to the underside of the slab. In the areas in question it was possible to replace slab panels with fillers in order to realize the pipe conduits.

At the Ku’damm site the Mark-A. Krüger Bauunternehmung also used the MEVA MTT stair tower with non-slip floors for safe ascent as well as more than 3,200 EuMax props for slab formwork up to a height of 5.50 m and BKB folding access platforms to allow work to be performed comfortably while standing on a 1.25-m-wide walking surface.

Construction manager Mathias Lippski looks back with satisfaction after the completion of the building shell: "With MevaDec in particular, we had a system at our disposal that could be used throughout for different slab heights and requirements and which was nevertheless light and easy to handle. MevaDec made a significant contribution to reducing the workload on the three rotating tower cranes and thus to the timely completion of the building shell."

Data & Facts

Project: Office and commercial building "Gloria", Berlin, Germany.

Principal: CENTRUM Projektabwicklung GmbH, Düsseldorf, Germany.

Contractor: Mark-A. Krüger Bauunternehmung GmbH, Bernau bei Berlin, Germany.

MEVA systems

- Mammut 350 wall formwork

- MevaDec slab formwork

- STB 450 support frame

- BKB folding access platform

- EuMax prop.

Engineering and support: MEVA Schalungs-Systeme GmbH, Berlin office, Germany.