The StarTec XT with the integrated combination tie hole unites three tying methods in one system. It is possible to switch between these with a flick of the wrist – without installing additional parts. You thus remain flexible and profit from significantly shorter formwork placing times when tying from one side. Another advantage: StarTec XT is fully compatible with StarTec and the lightweight, crane-independent AluStar.

StarTec XT is a real all-rounder for universal use in commercial and residential construction with a capacity of 60 kN/m² fresh concrete pressure. StarTec XT is fully compatible with StarTec and AluStar.

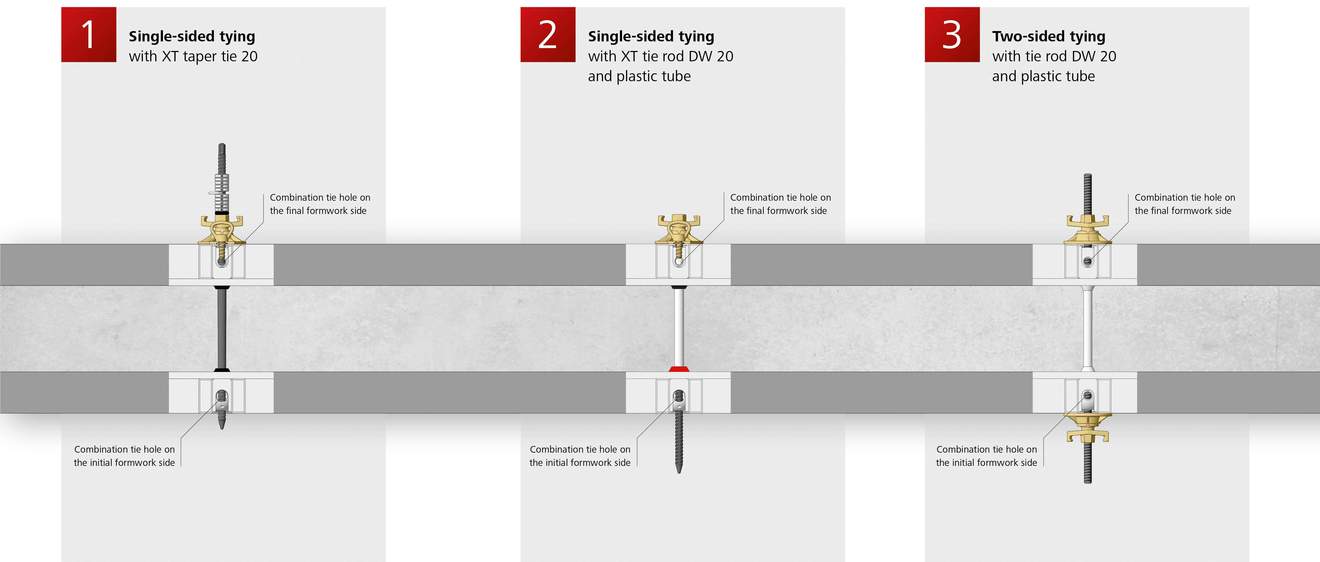

One system – 3 tying methods

Every construction site is unique, and the formwork requirements vary from project to project. StarTec XT creates an ideal basis for this as the system ensures that you remain flexible and well equipped for every task. Thanks to the smart combination tie hole, it is possible to select between three tying methods with a flick of the wrist. Every panel can be used for both initial and final formwork without additional assembly work. This saves times and simplifies the logistics. With StarTec XT, there are no additional accessories that require complex and time-consuming assembly work.

The smart combination StarTec XT tie hole

Ties with tapered anchor sleeves or DW 20 threads – the combination tie hole makes them possible. By using an internal body that can be positioned as required with the XT lever, the tying method can be changed easily with a flick of the wrist. The combination tie hole is integrated into the frame, ensuring that no parts protrude. No installation and removal are required.

Combination tie hole in thread position

Combination tie hole in anchor sleeve position

A wall full of ideas

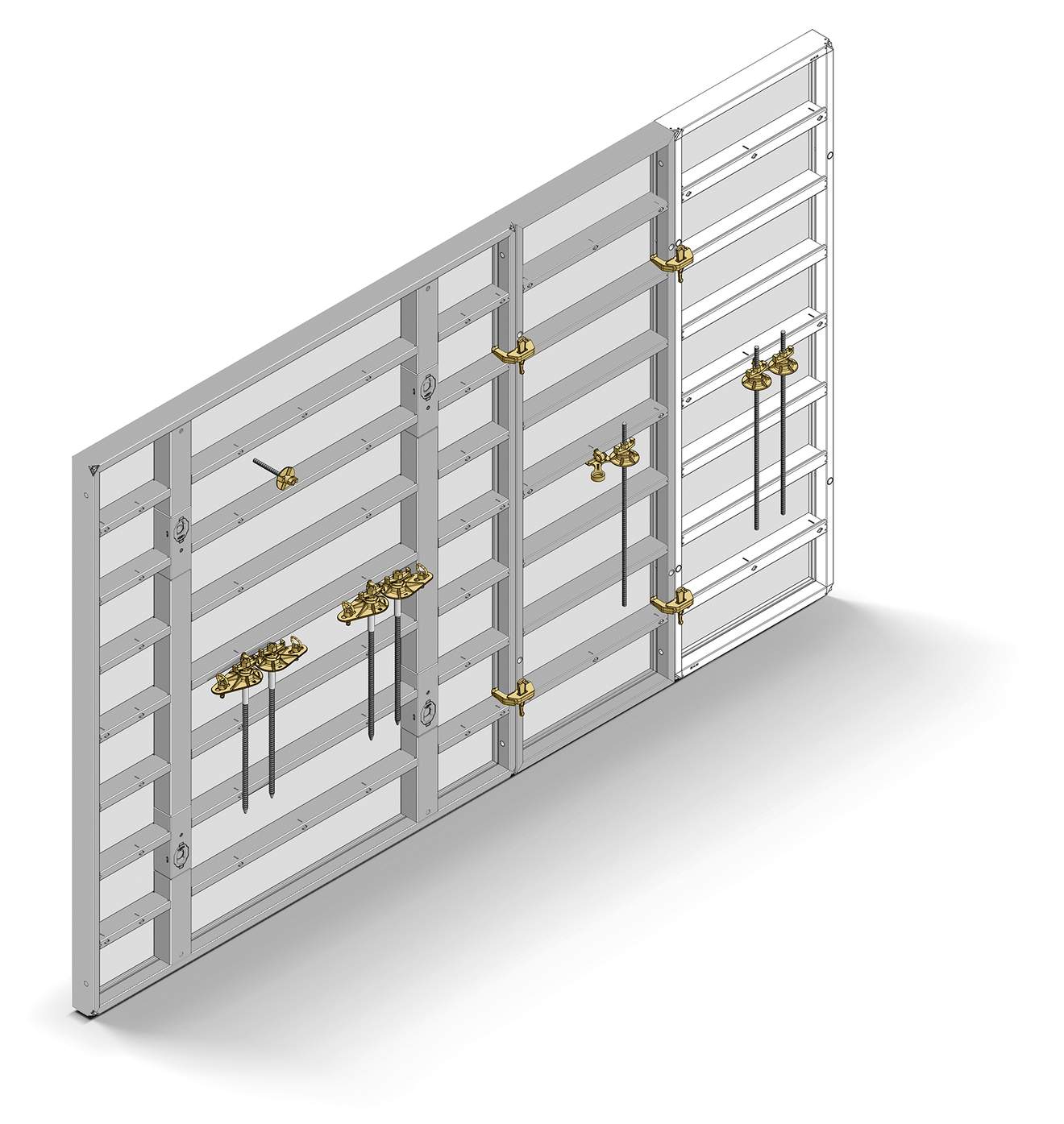

MEVA systems stand out due to a maximum of efficiency, quality and practical details. This also applies to the tried-and-tested multi-purpose formwork StarTec XT. With its uniform system components, small number of accessories and a perfectly coordinated range of options, has everything it takes to ensure that a MEVA system is the best solution for construction site applications.

- Multi-function profile

made of closed steel profiles with welded-in DW 15 threaded nuts for fast, non-positive attachment of accessories - Transport hole

to attach the crane sling 40, allowing for fast loading, unloading and relocation of panel stacks - Flange screw

All auxiliary equipment is connected non-positively using a single part - Combination tie hole

with a rotating body for single-sided and two-sided tying (three tying methods) - Closed profile

for a high degree of stability and easy cleaning – with a hot-dip galvanized surface - Bump notch

Fitted at four corners for panel widths of 135 cm and more to simplify adjustment and alignment with crow bar - AS assembly lock

serves as a panel connection to the surrounding groove - Alkus all-plastic facing

The alkus formwork facing does not absorb water, swell or shrink. The rugged, smooth surface guarantees first-class quality of the concrete even after repeated use

StarTec XT panels

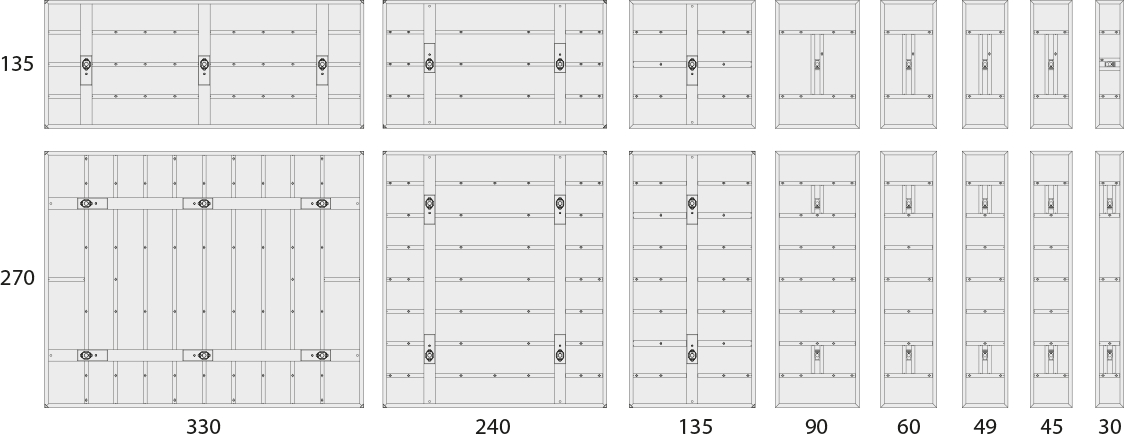

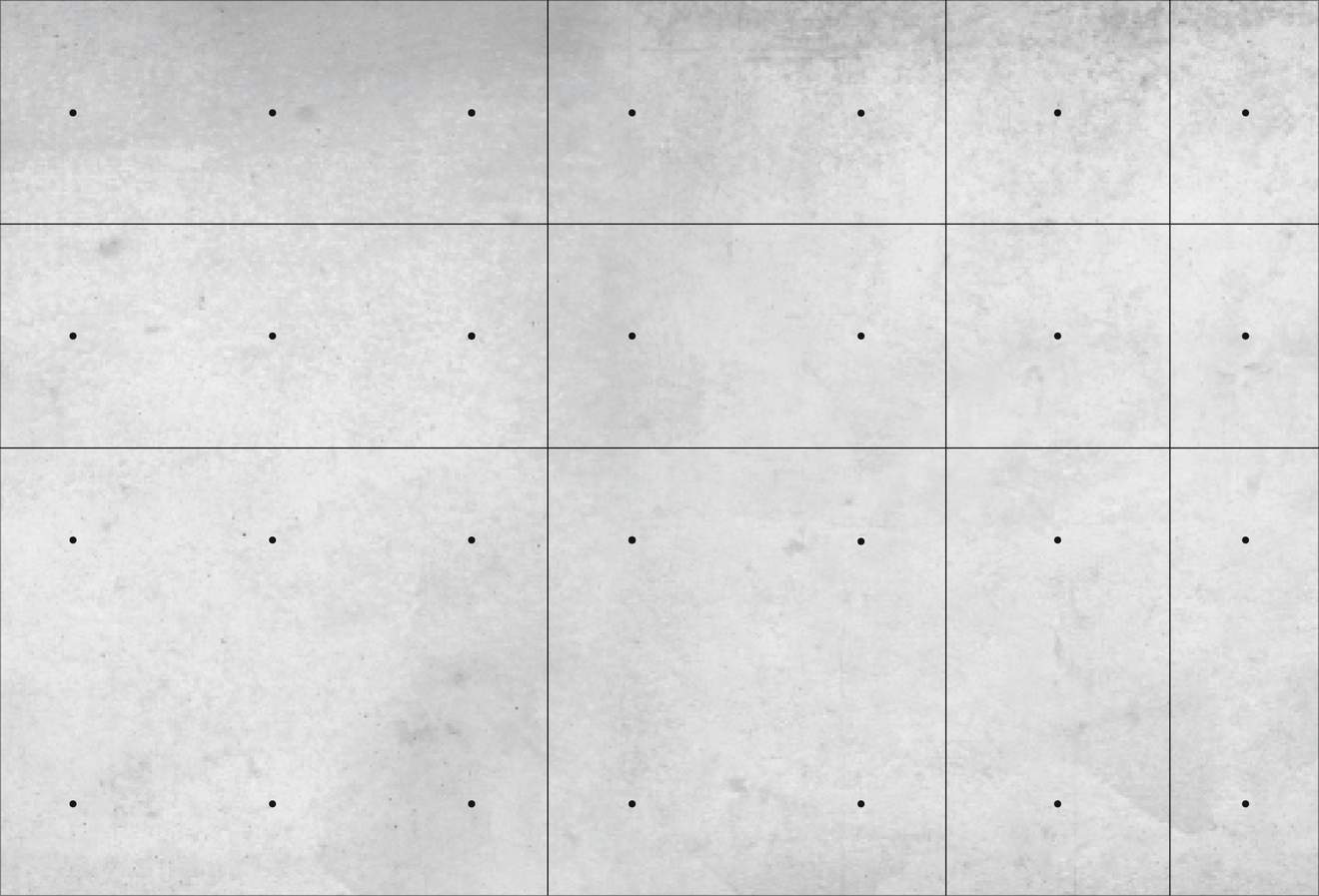

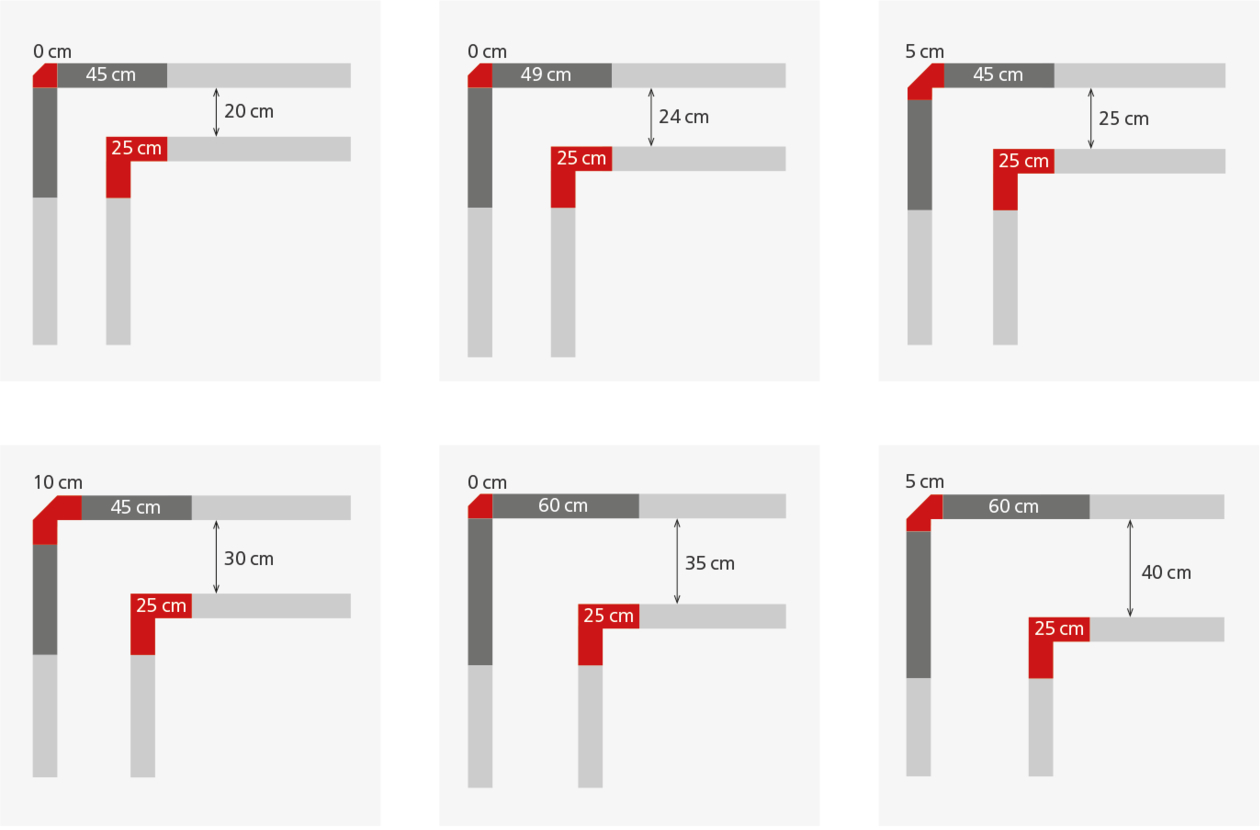

The StarTec XT panel dimensions and symmetrical internal tie holes result in a uniform tie hole and joint pattern for the highest architectural-concrete requirements. This applies to vertical, horizontal or a combination of vertical and horizontal formwork.

With the panel heights 330 cm, 270 cm and 135 cm as well as panel widths from 270 cm to 30 cm, StarTec XT enables quick adaptation to the geometry of the building. Thanks to the range of panels, all common wall thickness can be formed without filler areas.